-

High Sensitivity

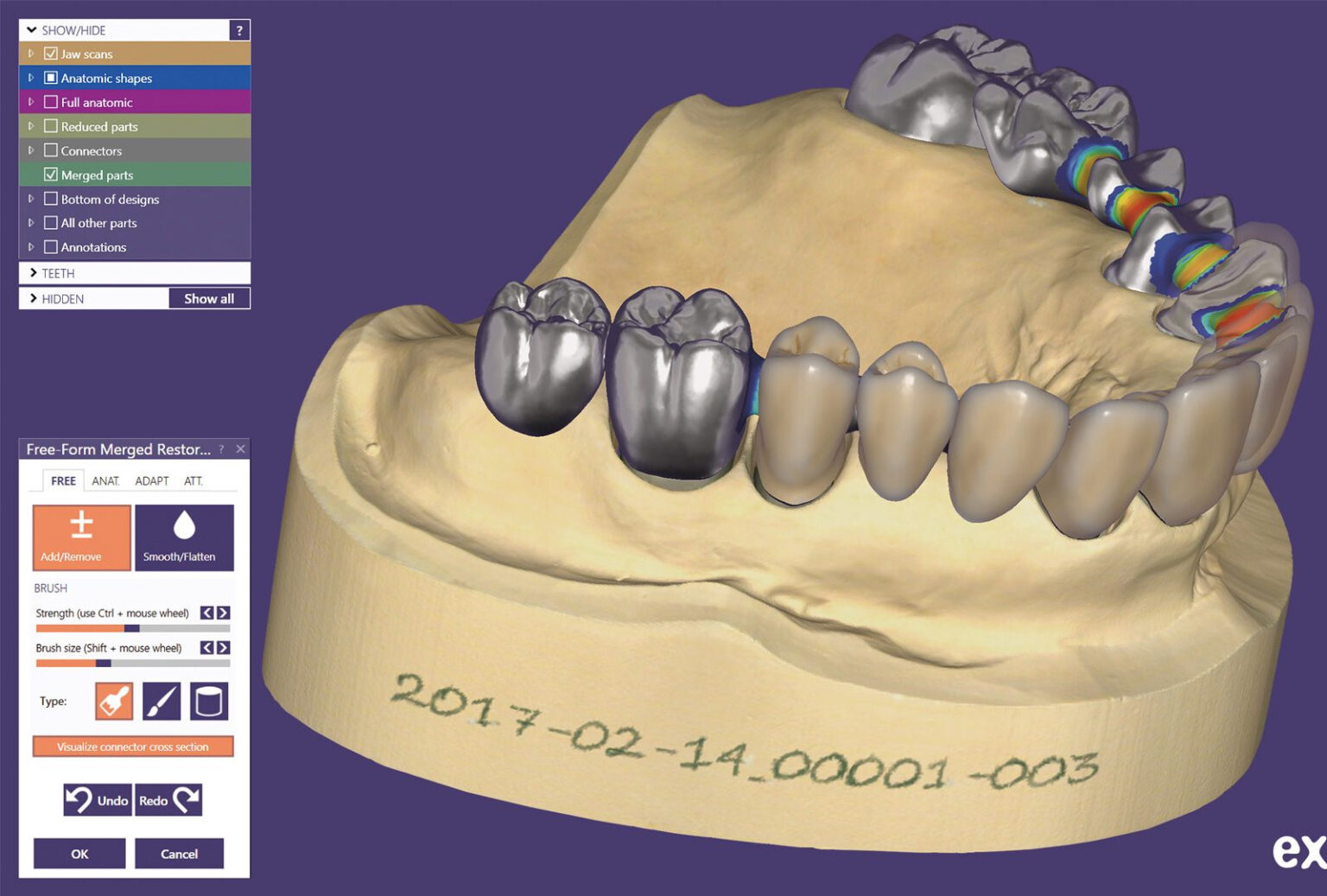

Prostheses produced with CAD/CAM technology offer high precision and perfect fit. Digital design and manufacturing processes increase patient comfort and prosthetic durability.

-

Fast Solution

CAD/CAM technology enables prostheses to be produced quickly and reliably.

What is CAD/CAM Prosthesis Application?

CAD/CAM Prosthodontics refers to the use of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies in restoring teeth and creating appropriate prostheses. CAD enables the digital modeling and design of prosthetic components based on precise measurements and anatomical data, while CAM facilitates the automated production of these components using various manufacturing techniques such as 3D printing or computer-controlled milling.

- Precision Production

- Aesthetic Design